Ares-J20 sawing and milling workstation + double-head end milling + robot + sorting line + complete set of vehicles

Key words:

Classification:

- Product description

-

Advantage

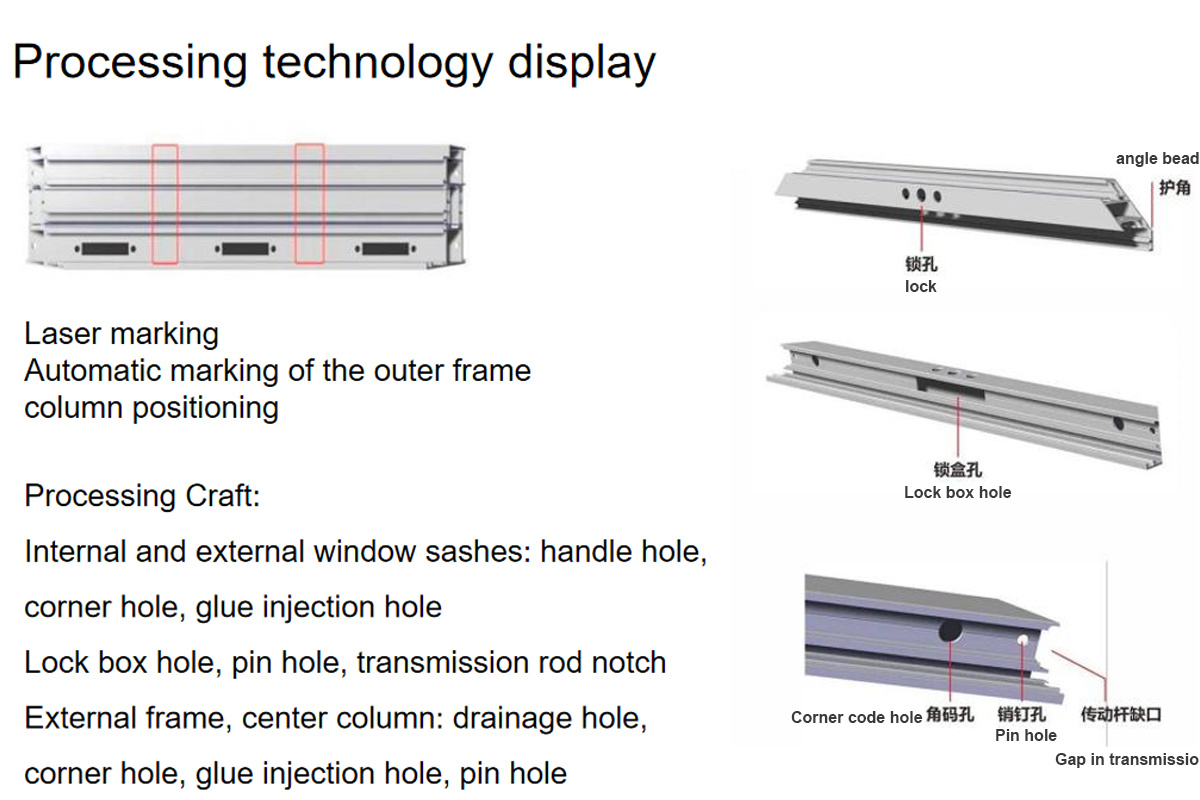

1. Equipped with 15-axis servo motor, 3 sets of fixed-angle servo cutting methods, 8+1 circulating loading and unloading platforms. Laser marking and milling holes at the back, laser marking at the front; one electric spindle each at the top, bottom, front and back, the front electric spindle can mill invisible drainage holes, automatic labeling device, and waste collection device. 2. It can realize 45-degree cutting, 45-degree and 90-degree mixed cutting, corner code holes, glue injection holes, lock holes, lock boxes, handle holes, installation holes, hardware gaps, corner protection cutting, stile marking, automatic labeling and other processing technologies at one time. 3. The three-axis CNC of the manipulator is adjustable and memorizable, which can realize flow operation and automatic material head recovery. Equipped with four sets of monitoring, it is safer to observe through the screen. 4. The feeding part is welded with thickened square tubes as a whole, and sandblasted and shot blasted after aging treatment to eliminate internal stress. The gantry is processed and formed in one time with higher precision. 5. The chassis base and main components are all made of cast one-piece technology, and are processed by CNC machining center milling and drilling, which is not easy to deform and more stable. 6. The main components and systems are all well-known brands to ensure the data processing and durability of the equipment for long-term operation. Industrial appearance sheet metal design, fully wrapped chassis, beautiful and safe. 7. It can be connected to mainstream door and window software, and can be processed by transmission. It can be connected to Xinger software and capture data in the cloud

Overall dimensions 18800*3700*2500 (excluding chip conveyor dimensions) Servo running speed 40-130m/min 18800*3700*2500 (excluding chip conveyor dimensions) 3150*500*700mm Sawing speed 15-50m/min Total weight about 9 tons Allowed unloading length 700≤L≤6800mm Total power 44kw Sawing length ≥300mm Input power 380V/50HZ (three-phase four-wire system) :Saw blade diameter Φ550mm Working air pressure 1.6mpa Profile processing range height 130, width 130mm Number of materials allowed on the loading table 8+1 circulation type Sawing method 45° left and right for bottom-out type, 90° for flat-out type Drilling method four spindles, front and back, top and bottom, the front spindle can rotate Laser processing method rear laser cutting + marking, front laser marking Main configuration parameters : Control system: Han's Intelligent Control/XINJE (special for Ares) Low-voltage electrical components: Schneider (France) Servo motor: Inovance (Huichuang)/XINJE Sawing spindle: Jintaihui (Guangdong, China)/Tianyang Drilling and milling spindle: Olispeed (Italy)/BEISU

Precision ball screw: PEK/MSM Linear guide: PEK/MSM Solenoid valve: AirTac Cylinder: AirTac Reducer: Faston (Taiwan, China) Laser: Chuangxin (top domestic brand)

Laser cutting head: ospri (top domestic brand) Water chiller: Teyu (Guangdong, China) Diamond saw blade: Kua Wushuang (top domestic brand) Printer: Honeywell (USA brand)

Related Products

Product inquiry

Filling in your phone and email information will help us to contact you in a timely manner and solve your problems as soon as possible.