Overall solution for intelligent production line of doors and windows

Key words:

Classification:

- Product description

-

Equipment advantages

◎The new "central brain" (five channels of the family system) through the overall context, experience more wisdom!

◎Independent five-channel-mutual independent processing zone, avoid interference, more collabo- rative work more efficient!

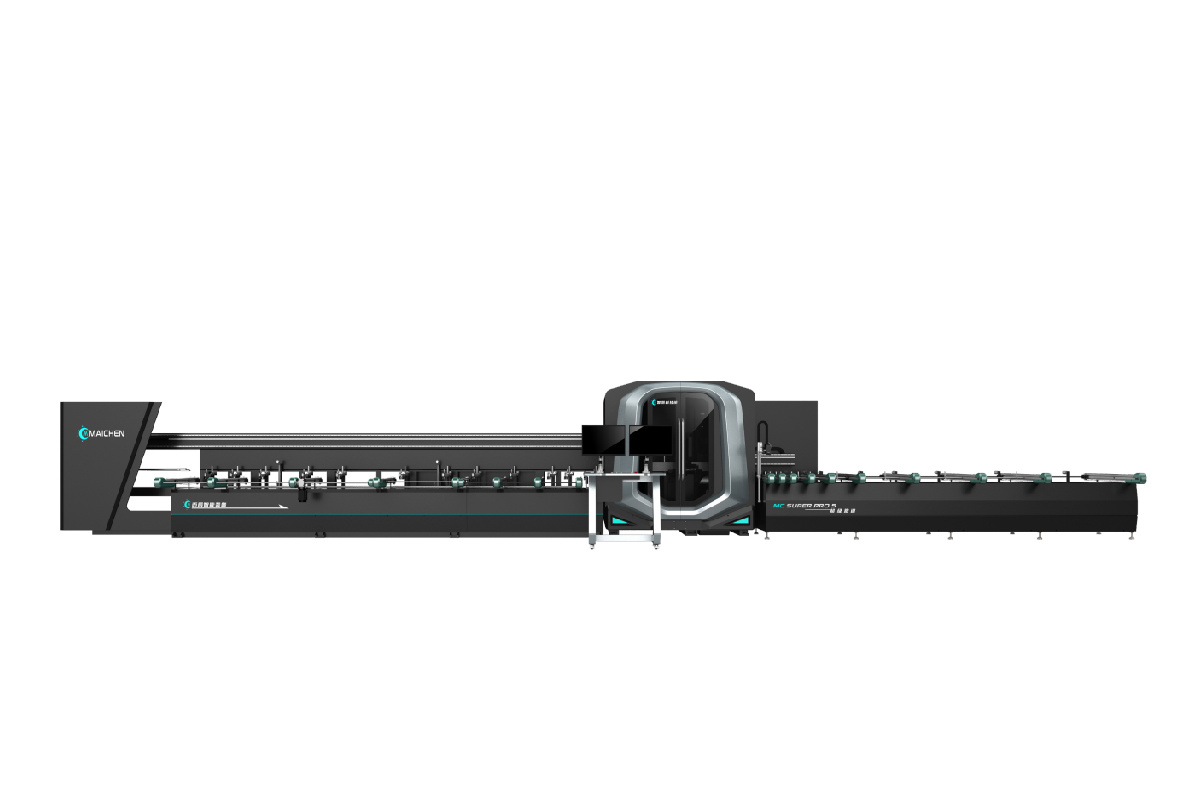

◎Runway type laser cutting device--longer travel, corner code hole glue hole process without time!

◎Intelligent manipulator: automatic error correction function, clip induction, automatic rotation, intelligent memory!

◎On the saw blade any Angle cutting- can cut any Angle and Angle, to meet a variety of processing needs!

◎Independent Angle cutting device-equipped with independent tail knife Angle cutting device, more than fast!

Input Voltage 380V/50HZ Total power 50kw Size of chip machine Approximately 3150×500×700mm working air pressure 1.6mpa Saw cut speed 15-50m/min Servo running speed 40-130m/min The length of the billet 1100≤L ≤7000mm Saw cut length ≥300mm Feeding table feeding quantity 8 + 1 branch cycle type Saw diameter Φ550 Saw cut Angle 45°, angle between -45°, and 90° Profile processing scope Height : 130×130mm Overall dimension 15900×3082×2410mm Total weight 9000kg Advantage:◎Cooperate with the host equipment to realize material transmission between processing equipment,

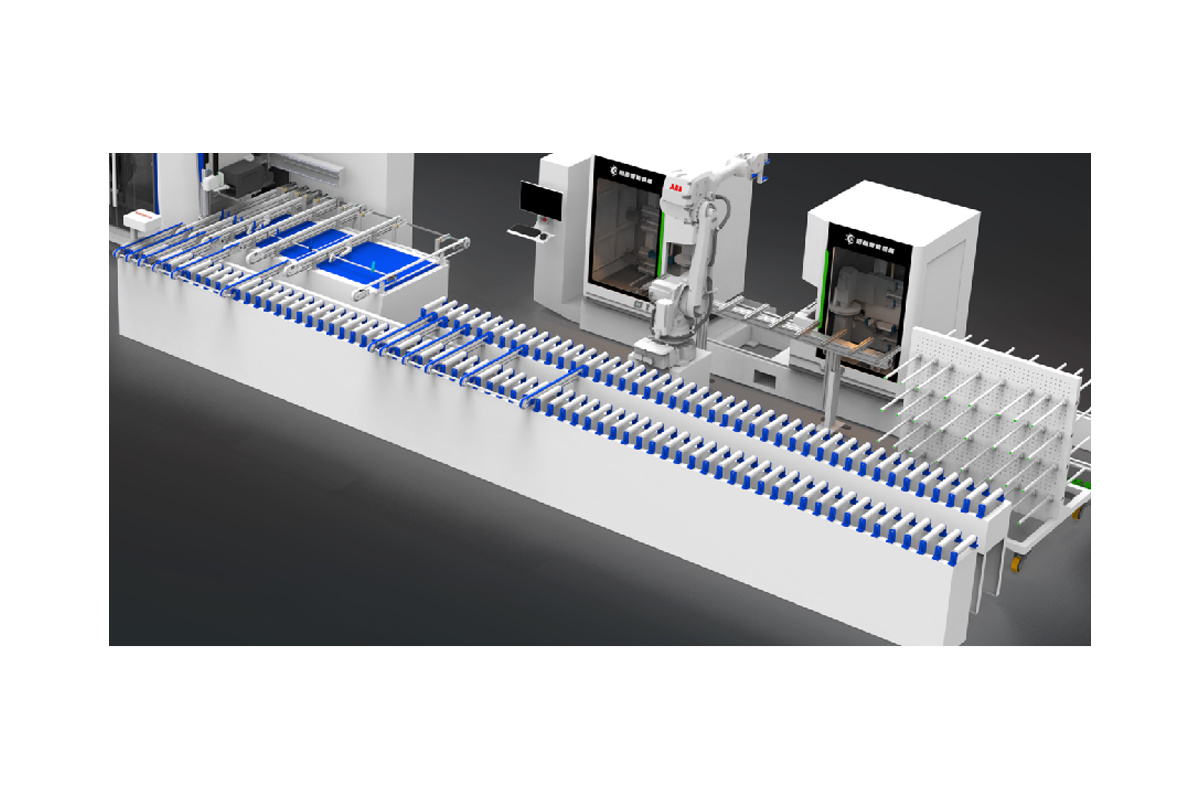

reduce handling time and labor intensity, and improve production efficiency.

◎ Equipped with variable frequency transmission motor, the speed variable frequency is adjustable, and can

be adjusted according to the production process rhythm

◎ Release a section at an interval of 15 seconds according to the profiles equipped with the sawing center.

◎ Single section length 4000mm-6000mm, adjust according to actual needs.

◎The maximum length of the sorting profile is 5000mm and the maximum width is 200mm (customizable).

◎ Equipped with transmission roller line and horizontal conveyor belt, the horizontal conveyor

belt can be raised and lowered as needed.

◎ Equipped with industrial scanner for sorting flow direction control according to process

requirements.

Machine Advantage:

Machine Advantage:◎The roller diameter is 50mm, the rubber thickness is 3mm, the rubber center distance is 120mm, the single motor power is 0.75KW, and the load is 30KG.

◎Mainly used for end surface processing of aluminum doors, windows, curtain walls and other mullion profiles

◎It is a new type of efficient automatic milling equipment developed after extensive market research to adapt to the development of high-end aluminum door and window processing industry and for high-end aluminum door and window processing.

◎High degree of automation, high processing precision, high production efficiency, labor saving, easy maintenance.

◎Through the setting of supporting device, pushing device, dragging device, etc., it can complete the working cycle of automatic feeding, milling, discharging, etc.;

◎Realize true seamless docking with upper and lower machines; greatly improve production efficiency while reducing labor intensity, and at the same time improve product quality.

Input power 380V/50Hz Working air pressure 1.6mpa Spindle power 4*3kw Total power 21.5KW Air supply 180L/min Milling width 150mm Milling height 150mm 150mm 450-3200mm Saw blade diameter 300mm Power machine head double machine head movement Spindle speed 3000r/min Servo motor 8*0.75kw Servo motor 4*0.85kw 4*0.85kw 6200*1300*2000mm

Equipment advantages:

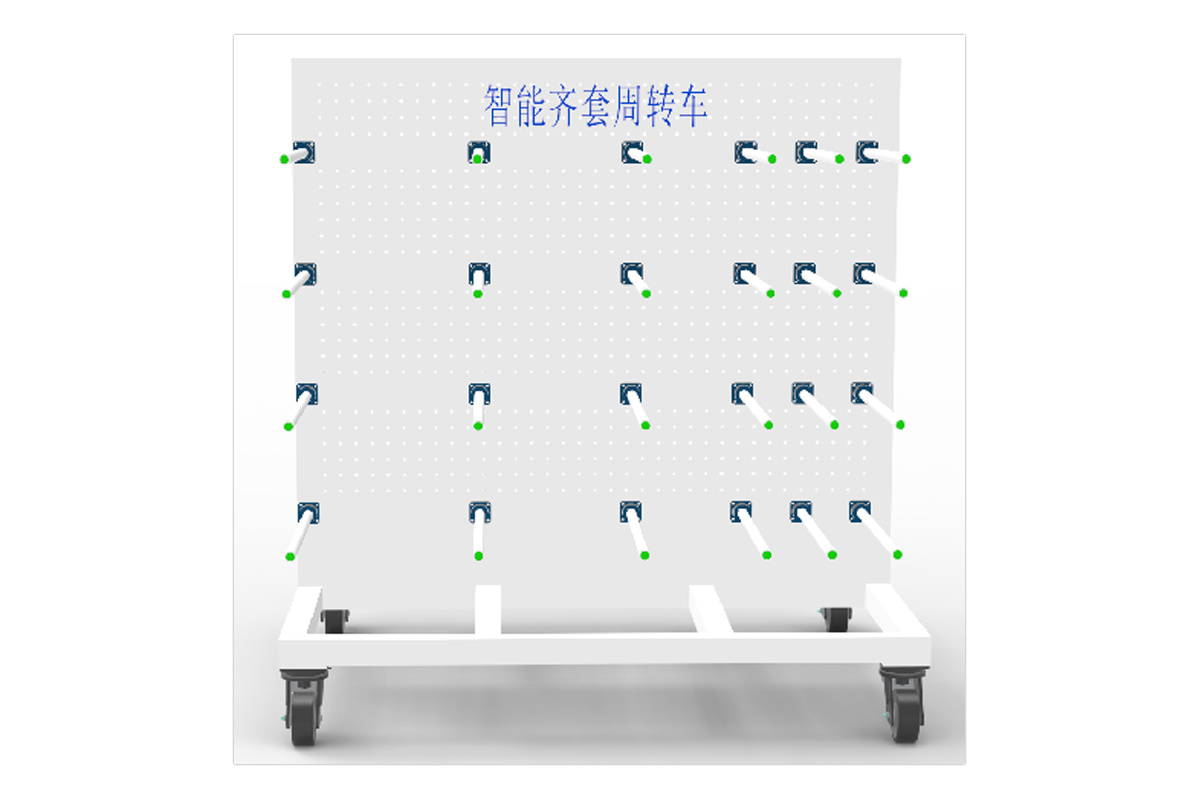

◎ It can store materials for multiple windows, with built-in PLC. By scanning the QR code, it can display which row of lights is on. It is intelligently aligned, saving labor and reducing the error rate.

◎It can be used with multiple alignment vehicles, and the alignment vehicles can be coded and distinguished through unified software. It can be built-in with mobile power and wireless WIFI to implement fleet control and operate more intelligently.

Related Products

Product inquiry

Filling in your phone and email information will help us to contact you in a timely manner and solve your problems as soon as possible.